Fraunhofer-Prepare-Project HATE-Fluor

Sustainable solutions for sealing technology

Users of poly- and perfluorinated alkyl substances (PFAS), also known as ‘forever chemicals’, are under considerable pressure due to the restriction proposal of the European Chemicals Agency (ECHA). This is one reason why many companies are looking for sustainable alternatives, especially for technical applications that have to withstand extreme conditions.

While fluorine-free substitutes are already available for various everyday applications, there is an urgent need for innovative solutions in specialised sections. In particular, sealing technology requires high thermal and chemical resistance, which so far can only be guaranteed by fluoroelastomers. One example of the many applications where high-quality and reliable seals are required is in hydrogen applications or vacuum systems for the production of photovoltaic modules. Without these seals, the progress of the energy transition could be significantly affected.

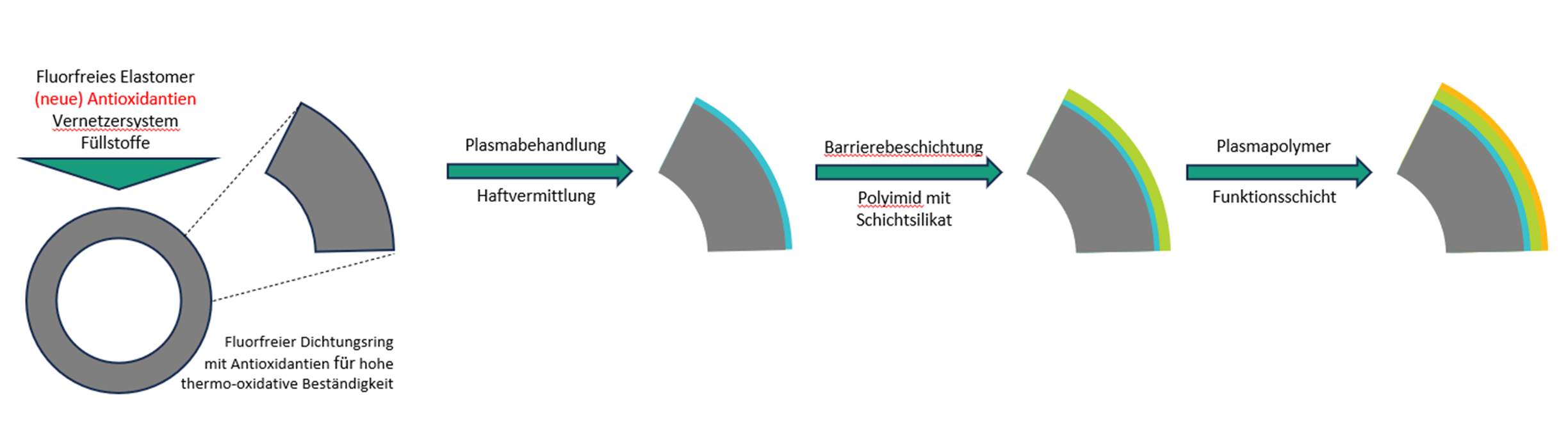

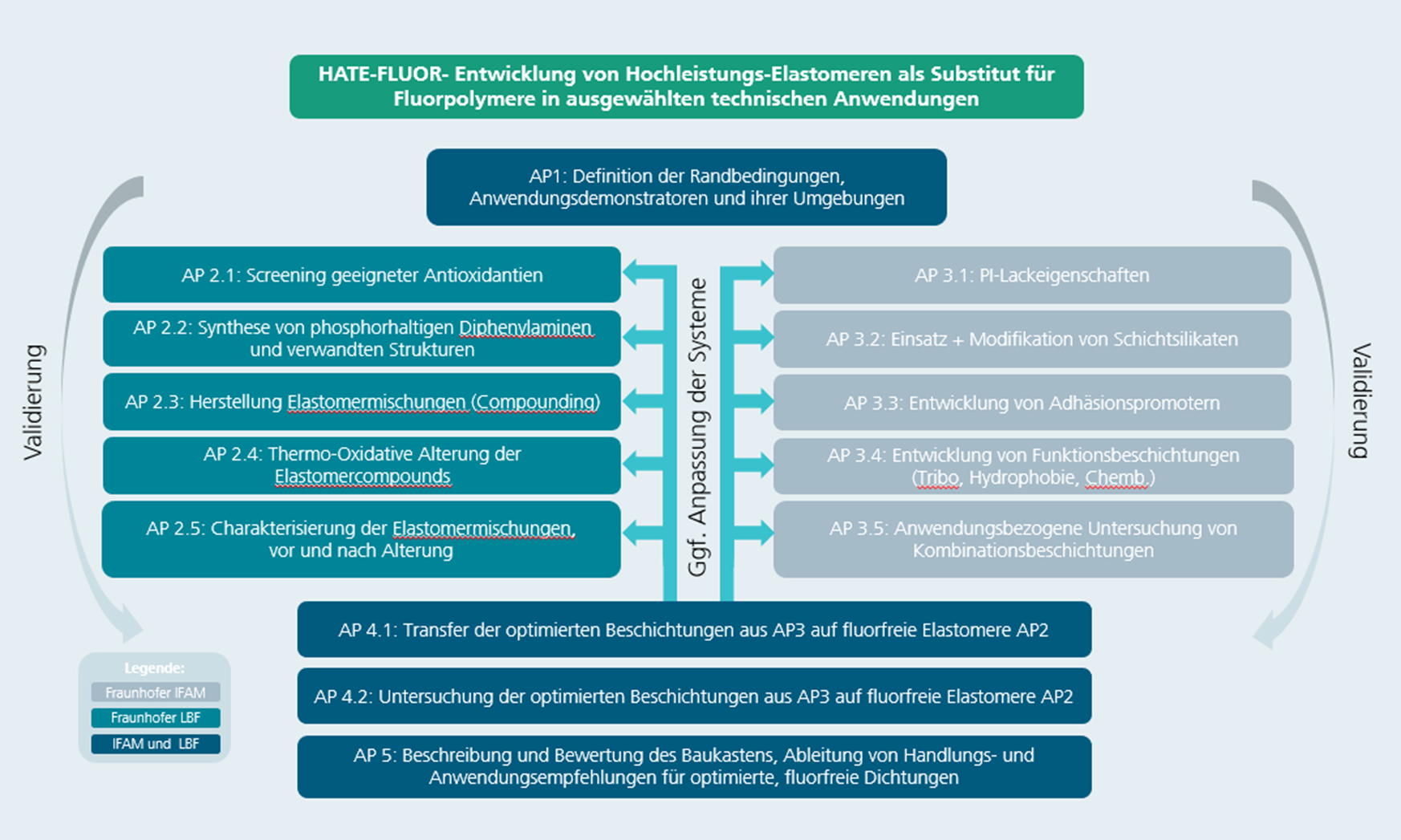

To meet this urgent need, the PREPARE initiative is developing fluorine-free coated elastomers that offer customisable modular solutions. This actively contributes to the creation of sustainable and high-performance materials that meet the requirements of the future.

Fraunhofer-Gesellschaft with its institutes LBF and IFAM

Fraunhofer-Gesellschaft with its institutes LBF and IFAM